Stainless Braided PTFE Brake Hose & AN Hose Ends

|

Step 1Wrap hose with glass filament strapping tape at cut-off point. Cut the hose squarely to length using a Cut-off Machine or a very fine tooth hacksaw. Remove tape and trim loose wires flush with tube. Burrs on bore of tube should be removed with a knife. Clean the hose bore. Sometimes the wire braid will flare out at one end and neck down at the other. This can be used to advantage. Slip two sockets back-to-back over the necked-down end of the hose and position them approximately 3 inches from each end. Mount the hose end nipple in a vice, then work the hose bore over the nipple to size the tube and aid in separating the braid from the tube prior to fitting the sleeve. Our Flaring Mandrel (Part No. 3157-3 or 3157-4) makes it much easier to separate the braid from the tube. |

|

Step 2Push the brass sleeve over the end of the tube and under the wire braid by hand. Complete positioning of the sleeve by pushing the end of the hose against a flat surface. Visually inspect to be sure the end of the tube butts against the inside shoulder of the sleeve. Set the sleeve barbs into the PTFE tube by pushing a round nose tapered punch or the flaring mandrel into the end of the tube. |

|

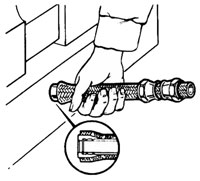

Step 3Hold the fitting in a vice with smooth or soft jaws. Lubricate the nipple and threads. Standard steel fittings can use petroleum lubricants; stainless steel fittings should use a moly lubricant (e.g., Molykote Type G). In any case, avoid lubricants containing chloride. Push hose over nipple with a twisting motion until seated against nipple chamfer. Push socket forward and start threading socket onto fitting threads. |

|

Step 4Tighten with a wrench until clearance to socket hex is no more than 1/32". Tighten further as needed to clock fittings or to align corners of socket and fitting hexes. Clean, proof test to twice operating pressure, and inspect all assemblies. |

To disassemble, unscrew and remove nipple. Slide socket back from the end of the hose by tapping on a flat surface. Remove sleeve with pliers and discard.

Important: Fittings can be disassembled and reused at least once; however, hose ends should be thoroughly inspected for signs of distortion, thread damage, and collapsing. A new sleeve should be used each time a hose end is used.